Carbon Steel

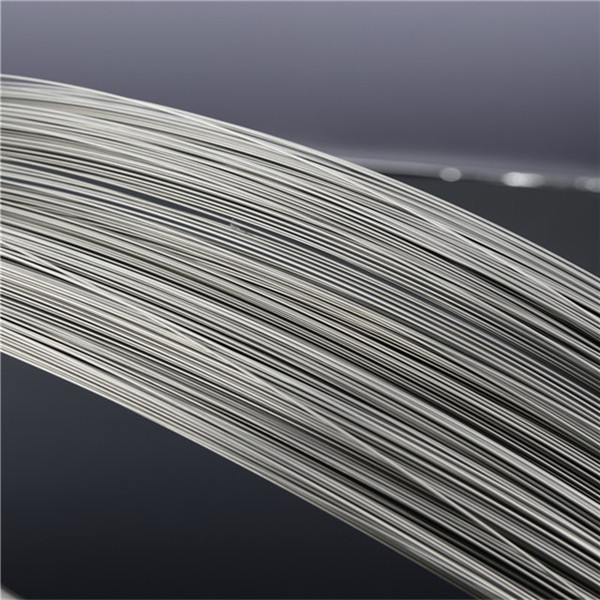

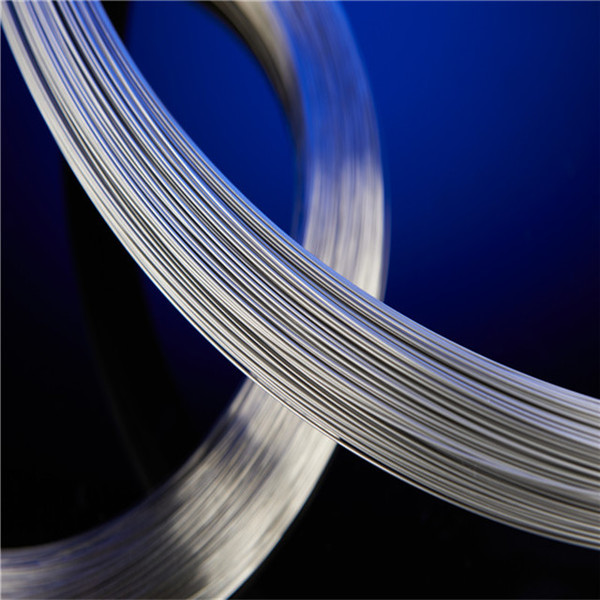

(Galvanized) Steel Wire

-

ASTM A475, DIN 17223, JIS G3547, DIN EN 10270, etc.

-

SAE1055, Class A/B, SWRH62B, SAE1075, SWRH82, etc.

-

NA

-

NA

Galvanized steel wire is divided into hot dip galvanized wire and electro galvanized wire. It is made of high quality carbon steel with different processes, including drawing molding, pickling, annealing, galvanizing, cooling and so on. GI wires are widely used in construction, springs, screen mesh, Wire Mesh, Brushes, Wheel Spokes, packaging and other fields.

Standard | ASTM A475, DIN 17223, JIS G3547, DIN EN 10270, ASTM A641, BS EN 10244, BS EN 10257, EN 50189, JIS G3521, ASTM A227M, ASTM 498, DIN 2076, JIS G3522, IS 4454, YB/T 5032, etc. |

Grade | SAE1006, SAE1008, SAE1010, Class A/B/C, SAE1040, SWRH42A, SWRH42B, SAE1045, SAE1055, SWRH62B, SAE1065, 65Mn, 72B, S45C, C55, S65C, S66C, S70C, SWP-A/B/V, SAE1070, SAE1075, SAE1080, SAE9254, SWRH72A, SWRH82A, SWRH82B, etc. |

Diameter | 0.13 ~ 15mm |

Surface Treatment | Hot Dip Galvanized, Electro Galvanized, Phosphate, Brass Coated, Copper Coated, etc. |

Tensile Strength | 290 ~ 550 Mpa; 1180 ~ 2760 Mpa, or higher as per request. |

Coating Mass | 12 ~ 800 g/m2, Class A/B/C/D/E, etc. |

Coil Weight | 10 kgs, 25 kgs, 50 kgs, 100 kgs, 200 kgs, 500 kgs, 1000 kgs, etc. |

Package | Coil, Drum, Spool, Z2, Z3, Wooden Reel, etc. |

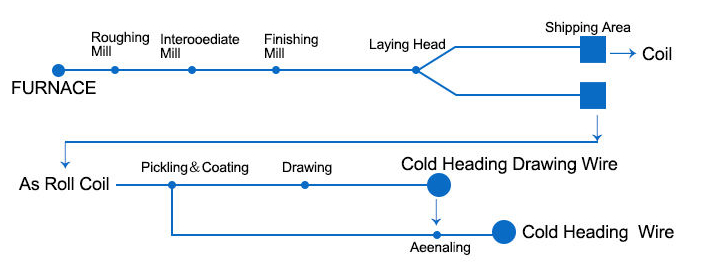

Manufacturing Process

Type of Packing

Mechanical Properties

High Carbon Steel Wire | |||||

Diameter(mm) | Tensile Strength ( Mpa ) | ||||

SL type | SM type | DM type | SH type | DH type | |

0.10 | . | . | 2710-3020 | . | 2800-3380 |

0.20 | . | . | 2500-2790 | . | 2800-3110 |

0.25 | . | . | 2420-2710 | . | 2720-3010 |

0.30 | . | 2307-2650 | 2370-2650 | 2660-2940 | 2660-2940 |

0.40 | . | 2270-2550 | 2270-2550 | 2560-2830 | 2570-2830 |

0.50 | . | 2200-2470 | 2200-2470 | 2480-2740 | 2480-2740 |

0.60 | . | 2140-2400 | 2140-2400 | 2410-2670 | 2410-2670 |

0.70 | . | 2090-2350 | 2090-2350 | 2360-2610 | 2360-2610 |

0.80 | . | 2050-2300 | 2050-2300 | 2310-2560 | 2310-2560 |

1.00 | 1720-1970 | 1980-2220 | 1980-2220 | 2230-2470 | 2230-2470 |

1.20 | 1670-1910 | 1920-2160 | 1920-2160 | 2170-2400 | 2170-2400 |

1.40 | 1620-1860 | 1870-2100 | 1870-2100 | 2110-2340 | 2110-2340 |

1.60 | 1590-1820 | 1830-2050 | 1830-2050 | 2060-2290 | 2060-2290 |

1.80 | 1550-1780 | 1790-2010 | 1790-2010 | 2020-2240 | 2020-2240 |

2.00 | 1520-1750 | 1760-1970 | 1760-1970 | 1980-2200 | 1980-2200 |

2.50 | 1460-1680 | 1690-1890 | 1690-1890 | 1900-2110 | 1900-2110 |

3.00 | 1410-1620 | 1630-1830 | 1630-1830 | 1840-2040 | 1840-2040 |

4.00 | 1320-1520 | 1530-1730 | 1530-1730 | 1740-1930 | 1740-1930 |

5.00 | 1260-1450 | 1460-1650 | 1460-1650 | 1660-1830 | 1660-1830 |

6.00 | 1210-1390 | 1400-1580 | 1400-1580 | 1590-1770 | 1590-1770 |

7.00 | 1160-1340 | 1350-1530 | 1350-1530 | 1540-1710 | 1540-1710 |

8.00 | 1120-1300 | 1310-1480 | 1310-1480 | 1490-1660 | 1490-1660 |

9.00 | 1090-1260 | 1270-1440 | 1270-1440 | 1450-1610 | 1450-1610 |

10.00 | 1060-1230 | 1240-1400 | 1240-1400 | 1410-1570 | 1410-1570 |

11.00 | . | 1210-1370 | 1210-1370 | 1380-1530 | 1380-1530 |

12.00 | . | 1180-1340 | 1180-1340 | 1350-1500 | 1350-1500 |

13.00 | . | 1160-1310 | 1160-1310 | 1320-1470 | 1320-1470 |

Features

Good Flexibility, Stability, Reliability

Smooth surface, free from scratch or knots.

High Strength Bearing Capacity.

Good Wearing Quality.

Quick Heat Radiation.

Applications

1) Mattress Spring

2) Mechanical Spring

3) Brushes

4) Cable Armouring

5) Wire Mesh

6) Wheel Spokes

7) Binding Wire

8) Accessories

9) Screen Mesh

10) Oil Dipstick

11) Crankshafts, Steering Knuckles, Gears, Spindles and Pumps

12) Others.

Production

China Metal Group provides the best quality to the customer, we develop cutting-edge solutions in technology, processes, and products. We use the latest technology to improve the quality and the performance of our products, upgrade our manufacturing processes, and use the latest methods in process analysis and design. We always challenge ourselves and have developed into an innovation-driven company.

Package

The products are packed and labeled according to the regulations or customer's requests. Great care is taken to avoid any damage which might be caused during storage or transportation. In addition, clear labels are tagged on the outside of the packages for easy identification of the product.

1) Our Standard Seaworthy Packing.

2) According to customer request.