Carbon Steel

Grain Oriented Electrical Silicon Steel - CRGO

-

JIS, AISI, EN, DIN, GOST, etc.

-

M0H-0.27, M4-0.27, 27P100, 23R085, etc.

-

0.23, 0.27, 0.30, 0.35mm

-

900-1200mm, or slitted strip.

The main purpose of cold-rolled grain oriented silicon steel strip is for transformer manufacturing, so it is also called cold-rolled transformer silicon steel. Grain oriented silicon steel has strong magnetic directionality; it has superior high magnetic permeability and low loss characteristics in the rolling direction of easy magnetization. The iron loss of the oriented steel strip in the rolling direction is only 1/3 of the transverse direction, the magnetic permeability ratio is 6:1, and the iron loss is about 1/2 of the hot rolled strip, and the magnetic permeability is 2.5 times of the latter.

Dimension

Thickness | Width | Slitting | Inside Diameter |

0.20mm, 0.23mm, 0.27mm, 0.30mm, 0.35mm | Original: 750~1290mm | 20~645mm | 508, 610mm |

Grade

Thickness, mm | JIS C2553 | AISI | ||

Grade | P1.7/50 W/kg (max) | Grade | P1.7/50 w/kg (max) | |

0.23 | 23G120 | 1.20 | M3-0.23 | 1.18 |

23G110 | 1.10 | M2-0.23 | 1.12 | |

23P105 | 1.05 | M1-0.23 | 1.05 | |

23P100 | 1.00 | M0H-0.23 | 1.00 | |

23P095 | 0.95 | |||

23P090 | 0.90 | |||

23P095 | 0.85 | |||

23R090 | 0.90 | |||

23R085 | 0.85 | |||

23R080 | 0.80 | |||

23R075 | 0.75 | |||

0.27 | 27G130 | 1.3 | M4-0.27 | 1.27 |

27G120 | 1.2 | M3-0.27 | 1.21 | |

27P110 | 1.1 | M1H-0.27 | 1.09 | |

27P100 | 1.0 | M0H-0.27 | 1.03 | |

0.30 | 30G140 | 1.4 | M5-0.3 | 1.39 |

30G130 | 1.3 | M4-0.3 | 1.32 | |

30G120 | 1.2 | M3-0.3 | 1.23 | |

30P115 | 1.15 | M2H-0.3 | 1.17 | |

30P110 | 1.1 | M1H-0.3 | 1.11 | |

30P105 | 1.05 | M0H-0.3 | 1.05 | |

30P100 | 1.00 | |||

30P095 | 0.95 | |||

0.35 | 35G155 | 1.55 | M6-0.35 | 1.57 |

35G145 | 1.45 | M5-0.35 | 1.45 | |

35P135 | 1.35 | M3H-0.35 | 1.28 | |

35P125 | 1.25 | M2H-0.35 | 1.22 | |

35P115 | 1.15 | M1H-0.35 | 1.16 | |

Technical Information

Type | Grade | Thickness (mm) | Density (kg/dm3) | P1.7/50 Max. Core loss (W/kg) | B8 Min. Induction (T) |

Conventional G Type | 23G110 | 0.23 | 7.65 | 1.1 | 1.8 |

27G120 | 0.27 | 7.65 | 1.2 | 1.8 | |

30G120 | 0.3 | 7.65 | 1.2 | 1.8 | |

30G130 | 1.3 | 1.8 | |||

30G140 | 1.4 | 1.8 | |||

35G130 | 0.35 | 7.65 | 1.30 | 1.8 | |

35G135 | 1.35 | 1.8 | |||

35G145 | 1.45 | 1.8 | |||

35G155 | 1.55 | 1.8 | |||

High Induction P Type | 23P085 | 0.23 | 7.65 | 0.85 | 1.87 |

23P090 | 0.9 | 1.87 | |||

23P095 | 0.95 | 1.87 | |||

27P090 | 0.27 | 7.65 | 0.9 | 1.88 | |

27P095 | 0.95 | 1.88 | |||

27P100 | 1 | 1.88 | |||

30P095 | 0.3 | 7.65 | 0.95 | 1.88 | |

30P100 | 1 | 1.88 | |||

30P105 | 1.05 | 1.88 | |||

30P120 | 1.2 | 1.88 | |||

35P115 | 0.35 | 7.65 | 1.15 | 1.88 | |

35P125 | 1.25 | 1.88 | |||

35P135 | 1.35 | 1.88 | |||

Domain Refined High Induction R Type | 23R080 | 0.23 | 7.65 | 0.8 | 1.87 |

23R085 | 0.85 | 1.87 | |||

23R090 | 0.9 | 1.87 | |||

27R085 | 0.27 | 7.65 | 0.85 | 1.87 | |

27R090 | 0.9 | 1.87 | |||

27R095 | 0.95 | 1.87 |

Characteristics of Insulating Coating

Item | Characteristics |

Composing Component | Inorganic coating. |

Surface Insulation Resistance | Surface insulation resistance (Guaranteed Value: 30 Ω·cm2 /side) and excellent insulation. |

Adhesion | Fine adhesion, adhesion level ≥ B, close combination of coating and substrate, unease to peel. |

Lamination Factor | Uniform coating and high Lamination factor make good lamination effect. |

Processability | Excellent stamping and welding ability. |

Heat Resistance | For the high magnetic induction type products, the coating can withstand 820℃ stress relieving annealing in non- oxidation environment. |

Corrosion Resistance | The coating can immune from the corrosion of insulating coil, mechanical oil, cooling coil, antifreezing oil, rust preventive oil and Freon. |

Limits of Hazardous Substances | The products comply with RoHS and REACH limited requirements for hazardous substances. |

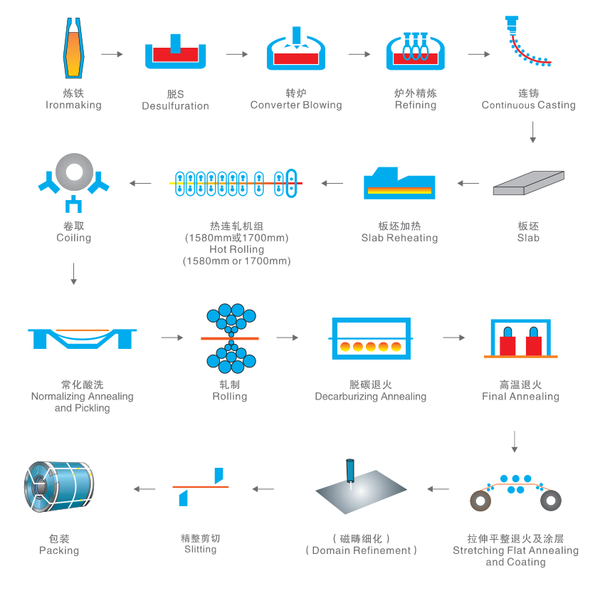

Manufacturing Process

Recommended Applications

Type | Conventional | High Induction | Domain Refined High Induction |

Large Motors | √ | √ | |

Large Transformers | √ | √ | √ |

Medium & Small Transformers | √ | √ | √ |

Distributing Transformers | √ | √ | |

Voltage Regulator | √ | √ | |

Reactor & Magnetic Amplifier | √ | √ | √ |

IF Transformer | √ | ||

Mutual Inductor | √ | √ | |

TV Transformer | √ | √ | |

Radio Transformer | √ | √ | |

Radio Broadcast Transformer | √ |

Production

China Metal Group provides the best quality to each customer, we develop cutting-edge solutions in technology, processes and products. We use the latest technology to improve the quality and the performance of our products, upgrade our manufacturing processes, and use the latest methods in process analysis and design. We always challenge ourselves and have developed into an innovation-driven company.

Package

The products are packed and labeled according to the regulations or customer's requests. Great care is taken to avoid any damage which might be caused during storage or transportation. In addition, clear labels are tagged on the outside of the packages for easy identification of the product.

1) Our Standard Seaworthy Packing.

2) According to customer request.