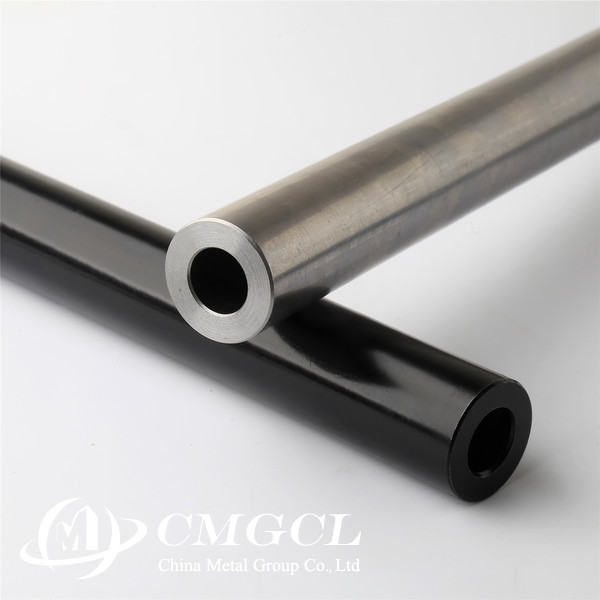

Carbon Steel

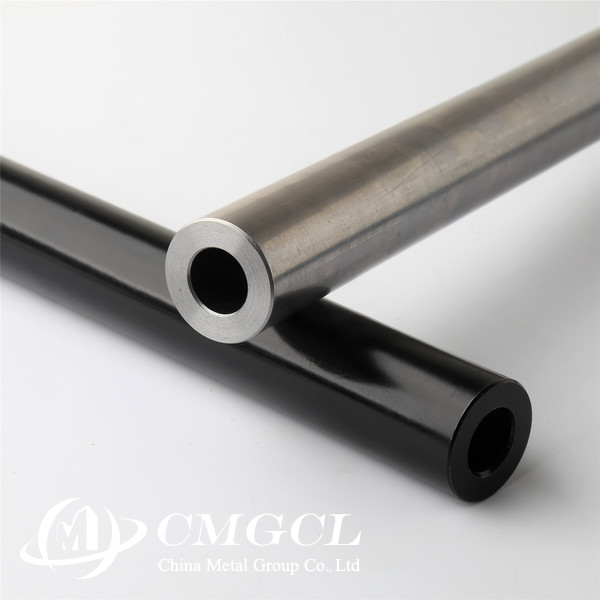

Seamless Steel Tube

-

ASTM A53, ASTM A106, ASTM SA423, API 5L, etc.

-

A53 Gr.B, A106 Gr.B, SA423 Gr.1, 100Cr6, etc.

-

0.5mm ~ 80mm

-

NA

Seamless steel tube, as the name suggests, is a pipe without seam or weld-joint. Seamless steel tube is a tubular section or hollow cylinder, usually but not necessarily of circular cross-section, used mainly to convey substances which can flow — liquids and gases (fluids), slurries, powders and masses of small solids.

Standard | ASTM A53, ASTM A106, ASTM SA423, ASTM A179, ASTM A192, ASTM A210, ASTM A213, ASTM A295, ASTM A333, ASTM A335, ASTM A519, DIN2391, DIN1629, DIN17175, DIN17176, EN10305, etc. |

Grade | A53 Gr.B, A106 Gr.A,B,C, SA423 Gr.1/2/3, A210 Gr.A1,Gr.C, STKM11A, STKM12B, STKM13A, SAE1020, SAE1045, ST35, ST45, ST52, ST35.8, ST45.8, P235GH, API 5L Gr.B, X42, X52, X56, etc. Alloy Grade: 100Cr6, E52100, 25CrMo4, 34CrMo4, 42CrMo4, SAE4130, SAE4140, SAE4145, etc. |

Outer Diameter | 3 ~ 914mm |

Thickness | 0.5 ~ 80mm, or SCH XX. |

Length | 3m, 5.8m, 6m, 9m, 12m, or as per request. |

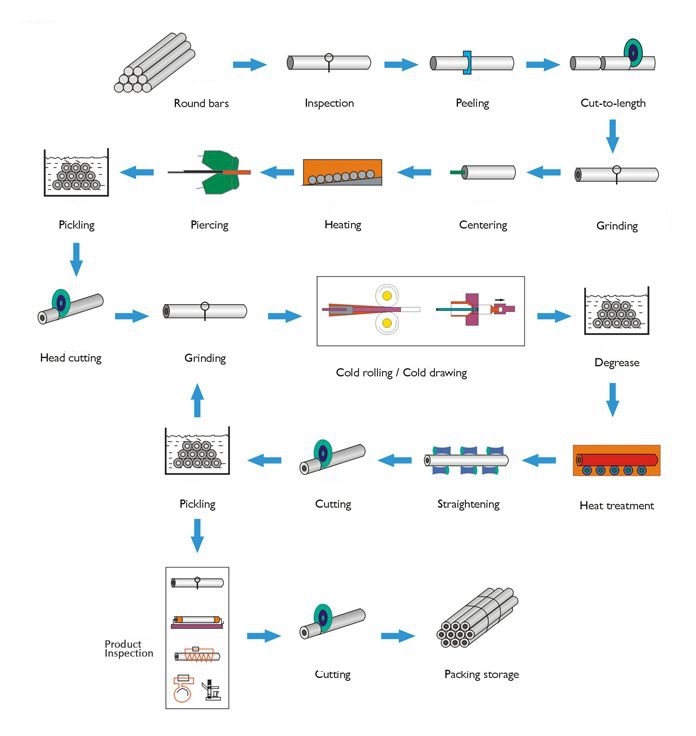

Manufacture Method | Cold Drawn, Cold Rolled, Hydraulic Cold Drawn, Hot Rolled, Hot Expanded and Depp Hole Drilling. |

Delivery Condition | As Rolled, Stress Relieved, Annealed, Normalized, Quenched+Tempered. |

End finish | Plain Ends, Bevelled, Cut Square, Grooved, Threaded and Coupling. |

Surface Treatment | Painted, Anti-Corrosion Oiling, Galvanizing, 3PE/3PP/FBE Coating, Epoxy Coating, etc. |

Chemical Composition & Mechanical Properties

Standard | Grade | Chemical Components (%) | Mechanical Properties | |||||

C | Si | Mn | P | S | Tensile Strength (Mpa) | Yield Strength (Mpa) | ||

ASTM A53 | A | ≤0.25 | - | ≤0.95 | ≤0.05 | ≤0.06 | ≥330 | ≥205 |

B | ≤0.30 | - | ≤1.2 | ≤0.05 | ≤0.06 | ≥415 | ≥240 | |

ASTM A106 | A | ≤0.30 | ≥0.10 | 0.29-1.06 | ≤0.035 | ≤0.035 | ≥415 | ≥240 |

B | ≤0.35 | ≥0.10 | 0.29-1.06 | ≤0.035 | ≤0.035 | ≥485 | ≥275 | |

ASTM SA179 | A179 | 0.06-0.18 | - | 0.27-0.63 | ≤0.035 | ≤0.035 | ≥325 | ≥180 |

ASTM SA192 | A192 | 0.06-0.18 | ≤0.25 | 0.27-0.63 | ≤0.035 | ≤0.035 | ≥325 | ≥180 |

API 5L PSL1 | A | 0.22 | - | 0.90 | 0.030 | 0.030 | ≥331 | ≥207 |

B | 0.28 | - | 1.20 | 0.030 | 0.030 | ≥414 | ≥241 | |

X42 | 0.28 | - | 1.30 | 0.030 | 0.030 | ≥414 | ≥290 | |

X46 | 0.28 | - | 1.40 | 0.030 | 0.030 | ≥434 | ≥317 | |

X52 | 0.28 | - | 1.40 | 0.030 | 0.030 | ≥455 | ≥359 | |

X56 | 0.28 | - | 1.40 | 0.030 | 0.030 | ≥490 | ≥386 | |

X60 | 0.28 | - | 1.40 | 0.030 | 0.030 | ≥517 | ≥448 | |

X65 | 0.28 | - | 1.40 | 0.030 | 0.030 | ≥531 | ≥448 | |

X70 | 0.28 | - | 1.40 | 0.030 | 0.030 | ≥565 | ≥483 | |

Manufacturing Process

Applications

Production

China Metal Group Co., Ltd provides the best quality to the customer, we develop cutting-edge solutions in technology, processes, and products. We use the latest technology to improve the quality and the performance of our products, upgrade our manufacturing processes, and use the latest methods in process analysis and design. We always challenge ourselves and have developed into an innovation-driven company.

Package

The products are packed and labeled according to the regulations or customer's requests. Great care is taken to avoid any damage which might be caused during storage or transportation. In addition, clear labels are tagged on the outside of the packages for easy identification of the product.

1) Our Standard Seaworthy Packing.

2) According to customer request.