Carbon Steel

Steel Wire Rope

-

EN 12385-4, ASTM, JIS, BS, DIN, etc.

-

Carbon Steel, Stainless Steel

-

NA

-

NA

Steel wire rope is made up of steel wires that are twisted into strands, the strands are in turn twisted to form of steel wire ropes in different sizes, depending on the desired strength of the steel wire rope. Steel wire rope is used across a wide spectrum of industries for many applications, such as elevator, lifting, crane, mine, fishing, telpher, petroleum, construction and so on.

Diameter | 2 ~ 80mm |

Construction | 1*7, 3*7, 7*7, 6*7+FC, 6*7+IWS, 6*19+FC, 6*19+IWS, 6*37+FC, 6*37+IWS, 6*37+IWR, 6x36+7x7, 7*19+WSC, 7*35W+WSC, 9*19S+IWR, 9*7+FC, 8*19W+FC, 8*19+IWRC, etc. |

Core | IWRC, FC, WSC and PP |

Lay Direction | RHRL, LHRL, RHOL |

Tensile Strength | 1200, 1370, 1470,1570,1670,1770,1870,1960, 2160, 2260 Mpa |

Surface Treatment | Ungalvanized, Electro Galvanized, Hot Dip Galvanized, PVC coated, etc. |

Length | 500m/Reel, 1000m/Reel, 2000m/Reel, 3000m/Reel, or as per request. |

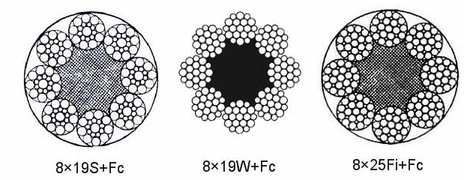

8X19S+FC, 8xl9W+FC, 8x25Fi+FC | ||||||||

Nominal Diameter | Weight | 8x19S+FC | 8x19W+FC | 8x25Fi+FC | ||||

Minimum Breaking Force / KN | ||||||||

mm | kg/100m | Dual Intensity /MPa | Single Intensity /MPa | |||||

1180/1770 | 1320/1620 | 1370/1770 | 1570/1770 | 1570 | 1620 | 1770 | ||

81) | 21.8 | 25.7 | 26.5 | 28.1 | 30.8 | 29.4 | 30.4 | 33.2 |

9 | 27.5 | 32.5 | - | 35.6 | 38.9 | 37.3 | — | 42 |

9.5 | 30.7 | 36.2 | 37.3 | 39.7 | 43.6 | 41.5 | 42.8 | 46.8 |

101) | 34 | 40.1 | 41.3 | 44 | 48.1 | 46 | 47.5 | 51.9 |

111) | 41.1 | 48.6 | 50 | 53.2 | 58.1 | 55.7 | 57.4 | 62.8 |

12 | 49 | 57.8 | 59.5 | 63.3 | 69.2 | 66.2 | 68.4 | 74.7 |

12.7 | 54.8 | 64.7 | 66.6 | 70.9 | 77.5 | 74.2 | 76.6 | 83.6 |

131) | 57.5 | 67.8 | 69.8 | 74.3 | 81.2 | 77.7 | 80.2 | 87.6 |

14 | 66.6 | 78.7 | 81 | 86.1 | 94.2 | 90.2 | 93 | 102 |

14.3 | 69.5 | 82.1 | — | 98.3 | — | — | — | |

15 | 76.5 | 90.3 | — | 98.9 | 108 | 104 | — | 117 |

161) | 87 | 103 | 106 | 113 | 123 | 118 | 122 | 133 |

17.5 | 104 | 123 | — | — | 147 | — | — | — |

18 | 110 | 130 | 134 | 142 | 156 | 149 | 154 | 168 |

191) | 123 | 145 | 149 | 159 | 173 | 166 | 171 | 187 |

20 | 136 | 161 | 165 | 176 | 192 | 184 | 190 | 207 |

20.6 | 144 | 170 | — | — | 204 | — | — | — |

221) | 165 | 194 | 200 | 213 | 233 | 223 | 230 | 251 |

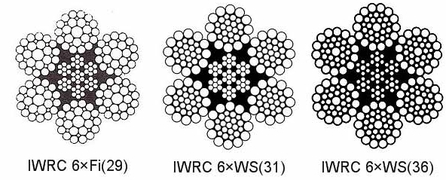

JIS Series of product structure—IWRC 6xFI(29)、IWRC 6xWS(31)、IWRC 6xWS(36) Breaking load | |||

The implementation of this family of products Q/320202AABL01-2006 Enterprise Standard (JISG3525: 1998) | |||

Structure | Steel Plug 29 Wire 6 Unit | Steel Western Watts Unit 31 Wire 6 Unit | Steel Western Watts 36 Wire 6 Unit |

IWRC 6xFi(29) | IWRC 6xWS(31) | IWRC 6xWS(36) | |

Nominal Diameter, mm | Breaking Load kN | Weight, kg/m | |

10 | 66.2 | 0.430 | |

11.2 | 83 | 0.539 | |

12.5 | 103 | 0.672 | |

14 | 130 | 0.843 | |

16 | 169 | 1.100 | |

18 | 214 | 1.390 | |

20 | 265 | 1.720 | |

22.4 | 332 | 2.160 | |

25 | 414 | 2.690 | |

28 | 519 | 3.370 | |

30 | 596 | 3.870 | |

31.5 | 657 | 4.270 | |

33.5 | 743 | 4.830 | |

35.5 | 834 | 5.420 | |

37.5 | 931 | 6.050 | |

40 | 1060 | 6.880 | |

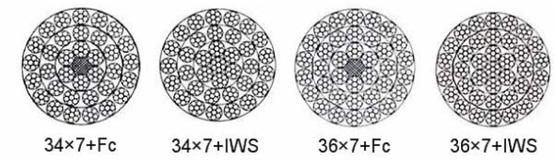

34x7+Fc, 34X7+IWS, 36x7+Fc, 36x7+IWS Mechanical Properties | ||||||||||||

Frame | 34x7+Fc | 34x7+IWS | 36x7+Fc | 36x7+IWS | ||||||||

Nominal wire rope diameter | Reference Weight | Nominal Tensile Strength / MPa | ||||||||||

mm | kg/100m | 1570 | 1670 | 1770 | 1870 | 1960 | ||||||

Minimum Pull Rope Breaking / KN | ||||||||||||

Fiber Core | Steel core | Fiber Core | Steel core | Fiber Core | Steel core | Fiber Core | Steel core | Fiber Core | Steel core | Fiber Core | Steel | |

16 | 99.8 | 110 | 124 | 128 | 132 | 136 | 140 | 144 | 147 | 152 | 155 | 160 |

18 | 126 | 139 | 157 | 162 | 167 | 172 | 177 | 182 | 187 | 193 | 196 | 202 |

20 | 156 | 172 | 193 | 200 | 206 | 212 | 218 | 225 | 230 | 238 | 241 | 249 |

22 | 189 | 208 | 234 | 242 | 249 | 257 | 264 | 272 | 279 | 288 | 292 | 302 |

24 | 225 | 248 | 279 | 288 | 296 | 306 | 314 | 324 | 332 | 343 | 348 | 359 |

26 | 264 | 291 | 327 | 337 | 348 | 359 | 369 | 380 | 389 | 402 | 408 | 421 |

28 | 306 | 337 | 379 | 391 | 403 | 416 | 427 | 441 | 452 | 466 | 473 | 489 |

30 | 351 | 387 | 435 | 449 | 463 | 478 | 491 | 507 | 518 | 535 | 543 | 561 |

32 | 399 | 440 | 495 | 511 | 527 | 544 | 558 | 576 | 590 | 609 | 618 | 638 |

Abbreviations of Wire Rope

Abbr. | Description |

FC | Fibre core |

FSWR | Flexible steel wire rope |

FW | Filler wire |

IWR | Independent wire rope |

IWRC | Independent wire rope core |

J | Jute (fibre) |

LH | Left hand lay |

LL | Lang's lay |

NR | Non-rotating |

OL | Orcfnary lay |

RH | Right hand lay |

S | Seale |

SF | Seale filler wire |

SW | Seale Warrington |

SWL | Safe working load |

TS | Triangular strand |

W | Warrington |

WF | Warriflex |

WLL | Waiting load limit |

WS | Warrington Seale |

Features

1. Smooth surface

2. High corrosion resistant

3. High fatigue strength

4. Excellent heat resistance

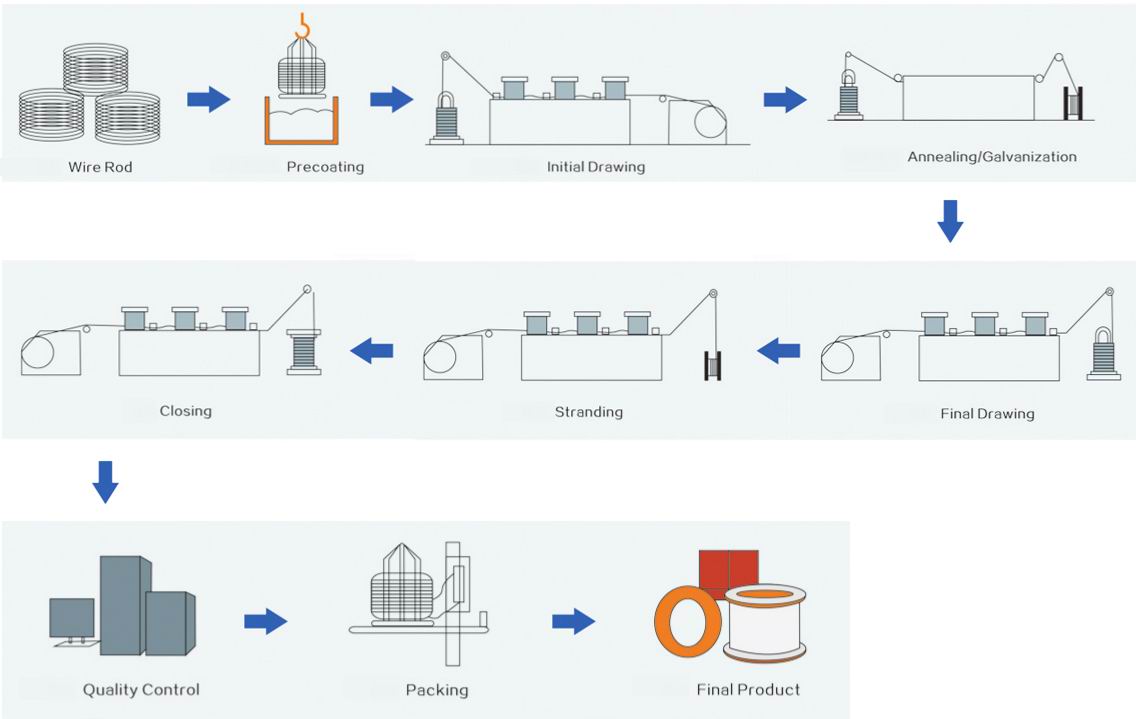

Manufacturing Process

Applications

Production

China Metal Group Co., Ltd provides the best quality to the customer, we develop cutting-edge solutions in technology, processes, and products. We use the latest technology to improve the quality and the performance of our products, upgrade our manufacturing processes, and use the latest methods in process analysis and design. We always challenge ourselves and have developed into an innovation-driven company.

Package

The products are packed and labeled according to the regulations or customer's requests. Great care is taken to avoid any damage which might be caused during storage or transportation. In addition, clear labels are tagged on the outside of the packages for easy identification of the product.

1) Our Standard Seaworthy Packing.

2) According to customer request.