Carbon Steel

High Speed Steel Bar

-

DIN, ASTM, JIS, GB, etc.

-

M2, M42, M35, H13, 1.2344, 1.2379, 1.2510, etc.

-

NA

-

NA

High speed steel bar is mainly used for cutting tool applications, such as twist drills, taps, milling cutters, reamers, saw blades, broaches, roll-to-inserts, gear cutters and other gear cutters. In addition to cutting tools with red hardness requirements, the material can also be used as cold work tool steels, such as die cutting, forming and embossing.

Standard | DIN, AISI, JIS, GB, etc. | |

High Speed Steel | M2, 1.3343, M35, 1.3243, M42, 1.3247, M20, M24, M26, M28, M30, M32, M38, M40, M45, M50 M52, W10, etc. | |

Tool Steel | H13, 1.2344, SKD61, D2, SKD11, 1.2379, 1.2510, O1, SKS3, 1.2510, 95MnWCr5, D3, SKD1, 1.2419, SKS31, H21, SKD5, 1.2581, P20, 35CrMo7, 1.2738, 1.2316, etc. | |

Sizes | Round Bar | 1.0 ~ 350mm |

Flat Bar | (1.0~150) x (20~900)mm | |

Length | 1m, 3m, 5.8m, 6m, or customized. | |

Hardness | HB205 ~ 255 | |

Surface | Black Surface with Oxygen Skin Grinded Peeled Polished Machined Silver | |

Delivery Status | Cold Drawn, Hot Rolled, Forged in annealed condition. | |

Heat Treatment

Annealing:

Annealing temperature is 860-880℃, keep this temperature by 2-4 hours, then cooling to 600℃ in the speed of 20-30℃/h.

For cold drawn process, the material will be processed with stress relieving annealing process under temperature of 600-700℃, and keep this temperature by 2 hours.

Quenching:

Pre-heating in two steps:

Heating temperature under 400-500℃ and 850-900℃.

Austenitizing temperature with 1185-1225℃

Heating coefficient 10-15 sec/mm, quenching under 580-620℃, then cooling to room temperature.

Tempering:

Tempering temperature under 540-560℃ , tempering 3 times, each time 1 hour, then cooling to room temperature.

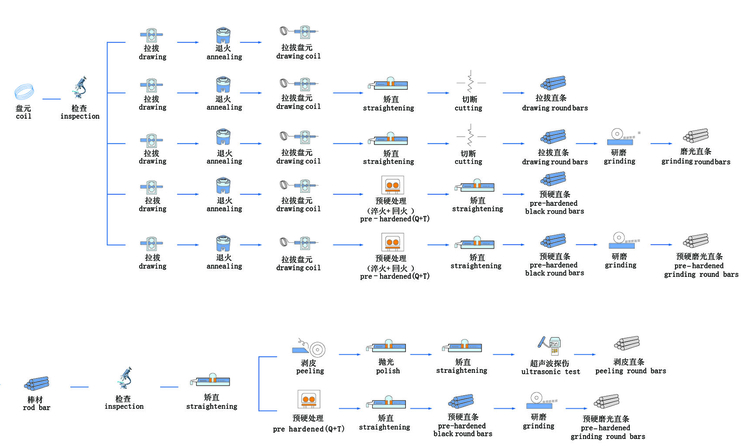

Manufacturing Process

Application

1.Twist drills

2.Milling cutters

3.Reamers

4.Saw blades

5.Broaches

6.Gear cutters

7.Die cutting, forming and embossing.

8.Others

Production

China Metal Group provides the best quality to the customer, we develop cutting-edge solutions in technology, processes, and products. We use the latest technology to improve the quality and the performance of our products, upgrade our manufacturing processes, and use the latest methods in process analysis and design. We always challenge ourselves and have developed into an innovation-driven company.

Package

The products are packed and labeled according to the regulations or customer's requests. Great care is taken to avoid any damage which might be caused during storage or transportation. In addition, clear labels are tagged on the outside of the packages for easy identification of the product.

1) Our Standard Seaworthy Packing.

2) According to customer request.