Carbon Steel

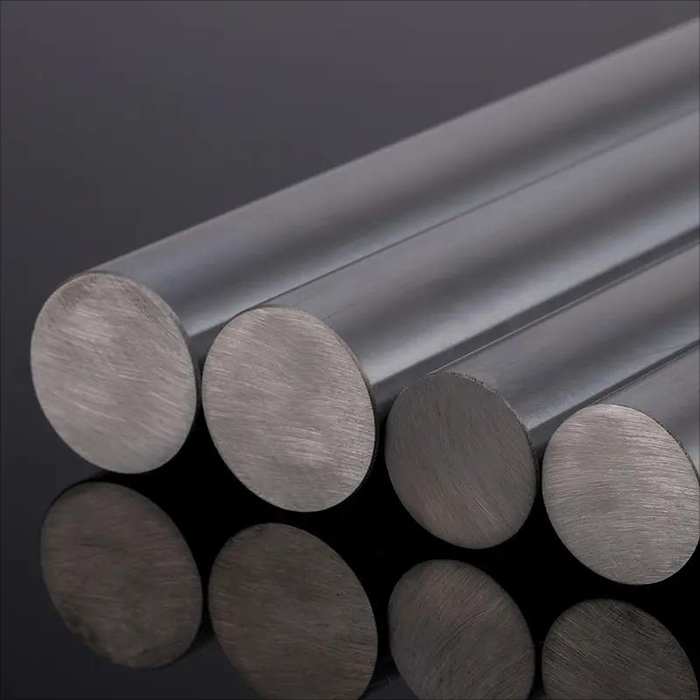

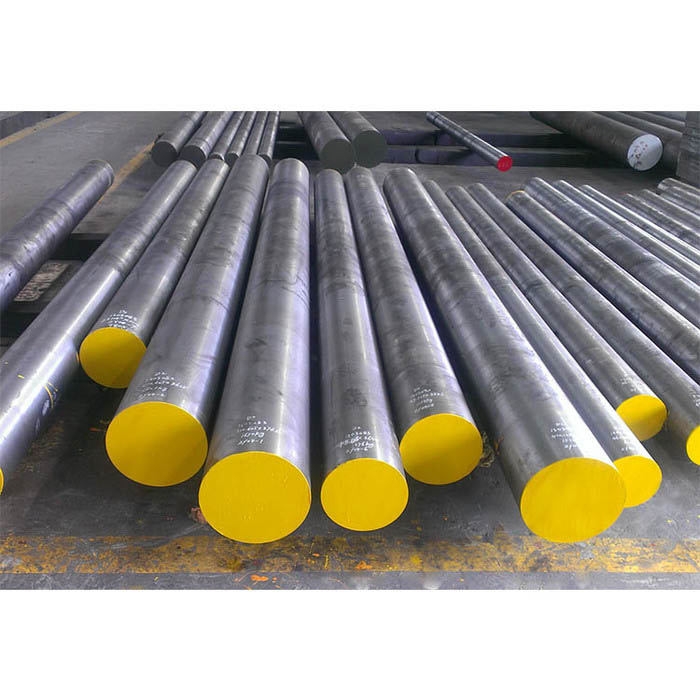

Steel Bar

-

JIS, ASTM, EN, DIN, ISO, GB, etc.

-

SAE 1045, SAE 1050, 11SMnPb30, 40Cr, 100Cr6, etc.

-

NA

-

NA

Steel bar is widely used in bolts, hardware, machinery, automobile and ships manufacturing industries, we are producing wide range of carbon steel bars and alloy steel bars, including round bars, hexagon bars, square bars and other customized steel bars.

Standard | JIS, ASTM, EN, DIN, ISO, GB, etc. |

Grade | SAE 1020, SAE 1035, SAE 1045, SAE 1050, SAE 1055. 20Cr, 40Cr, 15CrMo, 20CrMo, 35CrMo, 40CrMo, 42CrMo, 40CrNiMo, SAE52100, 100Cr6, 11SMnPb30, 28SiMnVB, 30SiMnVB, 30MnCrB5, SCM415, SCM420, SCM420, SCM440, 20CrNiMo, 40CrNiMo, SNCM220, SNCM439, SCr420, SCr440, 20X, 40X, 45X, SAE5120, SAE5140, SAE5145, SCr445, 12XM, 15XM, 20XM, 30XM, 35XM, 38XM, SCM430, SCM435, SAE4118, SAE4130, SAE4135, SAE4140, 38CrMoAl, SACM645, E7140, Y12Pb, 11SMnPb30, SUM22L, SUM24L, 12L14, 20Cr4, 41Cr4, 15XM, 13CrMo44, 18CrMo4, 25CrMo4, 34CrMo4, 34CrMo4, 41CrAlMo74. DWSi3, KM31, etc. |

Diameter | 5 ~ 600mm |

Length | 5.8m, 6m or as per request. |

Technique | Hot Rolled, Continuous Casting, Cold Drawn, etc. |

Surface Treatment | Bright, Painted, PE Coated, Galvanized, Polished, etc. |

Inspection | X-ray inspection, ultrasonic inspection, surface inspection, hydraulic testing, etc. |

Grade Comparison & Chemical Composition

Steel Grade | C | Si | Mn | P | S | Cr | Ni | Cu | ||

GB | SAE | JIS | ||||||||

20# | 1020 | S20C | 0.17~0.23 | 0.17~0.37 | 0.35~0.65 | ≤0.035 | ≤0.04 | ≤0.25 | ≤0.30 | ≤0.25 |

45# | 1045 | S45C | 0.42~0.5 | 0.17~0.37 | 0.5~0.8 | ≤0.035 | ≤0.04 | ≤0.25 | ≤0.25 | ≤0.25 |

50# | 1050 | S50C | 0.47~0.55 | 0.17~0.37 | 0.5~0.8 | ≤0.035 | ≤0.04 | ≤0.25 | ≤0.25 | ≤0.25 |

55# | 1055 | S55C | 0.52~0.6 | 0.17~0.37 | 0.5~0.8 | ≤0.035 | ≤0.04 | ≤0.25 | ≤0.25 | ≤0.25 |

20Cr | 5120 | SCr420 | 0.18~0.24 | 0.17~0.37 | 0.5~0.8 | ≤0.035 | ≤0.035 | 0.17~0.37 | ≤0.30 | ≤0.30 |

40Cr | 5140 | SCr440 | 0.37~0.44 | 0.17~0.37 | 0.5~0.8 | ≤0.035 | ≤0.035 | 0.80~1.10 | ≤0.30 | ≤0.30 |

20CrMo | 4118 | SCM420 | 0.17~0.24 | 0.17~0.37 | 0.40~0.70 | ≤0.035 | ≤0.035 | 0.80~1.10 | ≤0.30 | ≤0.30 |

35CrMo | 4135 | SCM435 | 0.32~0.40 | 0.17~0.37 | 0.40~0.70 | ≤0.035 | ≤0.035 | 0.80~1.10 | ≤0.30 | ≤0.30 |

42CrMo | 4140 | SCM440 | 0.38~0.45 | 0.17/0.37 | 0.5/0.8 | ≤0.035 | ≤0.035 | 0.90~1.20 | ≤0.30 | ≤0.30 |

38CrMoA1 | - | SACM645 | 0.35~0.42 | 0.20~0.45 | 0.30~0.60 | ≤0.035 | ≤0.035 | 1.35~1.65 | ≤0.30 | ≤0.30 |

20CrMn | 5115 | SMnC420 | 0.17~0.23 | 0.17~0.37 | 0.90~1.20 | ≤0.035 | ≤0.035 | 0.90~1.20 | ≤0.30 | ≤0.30 |

20CrNiMo | 8720 | SNCM220 | 0.17~0.23 | 0.20~0.30 | 0.60~0.95 | ≤0.035 | ≤0.035 | 0.40~0.70 | Ni:0.35~0.75 | |

Applications

1. Bolts

2. Bearing

3. Agricultural Implement

4. Machinery Parts

5. Hardware

6. Hardware Tools

7. Holesaw Caps

8. Mould

9. Automobile

10. Iron Core

11. Others.

Production

China Metal Group Co., Ltd provides the best quality to the customer, we develop cutting-edge solutions in technology, processes, and products. We use the latest technology to improve the quality and the performance of our products, upgrade our manufacturing processes, and use the latest methods in process analysis and design. We always challenge ourselves and have developed into an innovation-driven company.

Package

The products are packed and labeled according to the regulations or customer's requests. Great care is taken to avoid any damage which might be caused during storage or transportation. In addition, clear labels are tagged on the outside of the packages for easy identification of the product.

1) Our Standard Seaworthy Packing.

2) According to customer request.