GI / GL / PPGI / PPGL / ETP

Electro Galvanized Steel Coil & Sheet

-

JIS G3313, EN 10152, ASTM A591, GB 15675, etc.

-

SECC, SECD, SECE, DC01+ZE, etc.

-

0.5 ~ 3.0mm

-

50 ~ 1800mm

Electro galvanized steel is made by applying galvanizing to the surface of cold rolled steel using an electrochemical method, it protects the steel against corrosion. It has different post-treatment options, including non-treatment, chromate, phosphate and anti-fingerprinting. Its typical applications include home appliances, vehicle outer panels and construction materials.

Standard | JIS G3313, EN 10152, ASTM A591, GB 15675, etc. |

Grade | SECC, SECD, SECE, SECF, etc. DC01/DC03/DC04/DC05/DC06/DC07+ZE |

Coating | Z16/16, Z20/20, Z30/30, Z40/40, etc. |

Thickness | 0.5 ~ 3.0mm |

Width | 50 ~ 1800mm |

Length | As per request. |

Surface | AFP, N5, Phosphate, Oil, Chromate, etc. |

Roll ID | 508mm, 600mm |

Weight per Package | According to the request |

Mechanical Properties

JIS G3313 | EN 10152 | Yield Strength Mpa | Tensile Strength Mpa | Elongation (%) | |||||

Thickness (mm) | |||||||||

Grade | Grade | 0.4~0.6 | 0.6~1.0 | 1.0~1.6 | 1.6~2.3 | 2.3~2.5 | ≥2.5 | ||

SECC | DC01 (1.0330) | 280 max. | 270 ~ 410 | 34 min. | 36 min. | 37 min. | 38 min. | 38 min. | 39 min. |

SECD | DC03 (1.0347) | 240 max. | 270 ~ 370 | 36 min. | 38 min. | 39 min. | 40 min. | 40 min. | 41 min. |

SECE | DC04 (1.0338) | 220 max. | 270 ~ 350 | 38 min. | 40 min. | 41 min. | 42 min. | 42 min. | 43 min. |

SECF | DC05 (1.0312) | 200 max. | 270 ~ 330 | 40 min. | 42 min. | 43 min. | 44 min. | 44 min. | 45 min. |

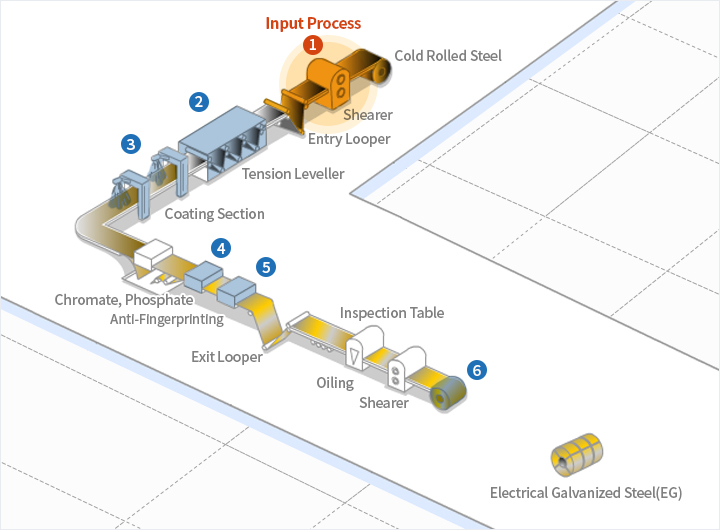

Manufacturing Process

Main Features

1. Good corrosion resistance, fine and uniform combination, not easy to be corrosive gas or liquid into the interior.

2. Because zinc layer is relatively pure, it is not easy to be corroded in acid or alkali environment. Protect the steel body effectively for a long time.

3. After chromic acid passivation, it can be used in various colors. It can be selected according to customers' preference. The galvanizing is beautiful and decorative.

4. The zinc coating has good ductility and will not easily fall during various bending, handling and impact.

The difference between electro galvanizing and hot galvanizing

1. There is a big difference in the amount of galvanizing between hot-dip galvanized sheet and electro-galvanized sheet. The amount of hot-dip galvanized sheet cannot be too small. Generally, the minimum is 50-60 g/m2 on both sides, and the maximum is 600 g/m2. The galvanized layer of the electro galvanized sheet can be very thin, the minimum is 15 g/m2.

2. Hot-dip galvanized sheet and electro-galvanized sheet are fundamentally different in the coating structure. There is a slightly brittle compound layer between the pure zinc coating of the hot-dip galvanized sheet and the steel strip substrate. When the pure zinc coating crystallizes, zinc flowers are mostly formed, and the coating is uniform and free of pores. The zinc atoms of the electro galvanized sheet layer are only deposited on the surface of the steel strip, and they are attached to the surface of the steel strip by physical action.

Applications

1) Refrigerator

2) Air Conditioning

3) Microwave Ovens

4) Washing Machine

5) Automobiles: air filters, fans, fuel tanks, etc.

6) Electrical Switch Board

7) Building Constructions: interior and exterior decoration, roofing, ductworks, HVAC products, flashing, doors, sashes, etc.

Production

China Metal Group provides the best quality to the customer, we develop cutting-edge solutions in technology, processes, and products. We use the latest technology to improve the quality and the performance of our products, upgrade our manufacturing processes, and use the latest methods in process analysis and design. We always challenge ourselves and have developed into an innovation-driven company.

Package

The products are packed and labeled according to the regulations or customer's requests. Great care is taken to avoid any damage which might be caused during storage or transportation. In addition, clear labels are tagged on the outside of the packages for easy identification of the product.

1) Our Standard Seaworthy Packing.

2) According to customer request.