GI / GL / PPGI / PPGL / ETP

Tinplate

-

JIS G 3303, ASTM A623M, EN 10202, ISO 11949, etc.

-

MR, SPCC, L, D

-

0.12 ~ 0.6mm

-

15 ~ 1050mm

Tinplate (SPTE/ETP) is a common name of electroplated tin steel sheets, which coated with commercial pure tin on both sides. Tin mainly acts to prevent corrosion and rust. It combines the strength and formability of steel with the corrosion resistance, solderability and aesthetic appearance of tin in a material with corrosion resistance, non-toxicity, high strength and good ductility. Tinplate has a wide range of coverage in the packaging industry because of its good sealing, preservation, light-proof, ruggedness and unique metal decoration charm. Besides, it has strong antioxidant, diverse styles and exquisite printing, tinplate is widely used in packaging industrial.

Standard | JIS G3303, ASTM A623M, EN 10202, EN 10203, ISO 11949, GB/T 2520, etc. |

Steel Type | MR, SPCC, L, D |

Temper | T1, T2, T3, T4, T5, DR7, DR8, DR9, etc. |

Annealing | CA (Continuous Annealing) & BA (Batch Annealing) |

Coating | 1.1/1.1, 2.8/2.8, 5.6/5.6, 8.4/8.4, 11.2/11.2 (g/m2) |

Thickness | 0.12 ~ 0.6mm |

Width | 15 ~ 1050mm |

Length | As per request. (Both Coil & Sheet are workable) |

Surface Finish | Bright, Stone, Silver, Matte finish with passivation treatment; Painted, DOS oil |

Coil Inside Diameter | 420 / 508mm |

Passivation | 300 / 311 |

Oiling | DOS |

Surface Finish

Marks | Surface Finish | Characteristics |

B | Bright Surface | Glazed surface obtained after melting treatment of electrotinned smooth raw material strip featuring certain oriented rubstone figure. |

R | Stone Surface | Glazed surface obtained after melting treatment of electrotinned raw material strip featuring certain oriented rubstone figure. |

S | Silver Surface | Glazed surface obtained after melting treatment of electrotinned raw material strip with rough matt surface. |

M | Matte Surface |

Temper Standard

JIS G3303 | ASTM A623M | DIN EN 10202 | GB/T 2520 |

T-1 | T-1 (T49) | TS230 | T-1 |

- | - | - | T-1.5 |

T-2 | T-2 (T53) | TS245 | T-2 |

T-2.5 | - | TS260 | T-2.5 |

T-3 | T-3 (T57) | TS275 | T-3 |

- | - | TS290 | T-3.5 |

T-4 | T4 (T61) | TH415 | T-4 |

T-5 | T5 (T65) | TH435 | T-5 |

- | DR-7.5 | TH520 | DR-7M |

DR-8 | DR-8 | TH550 | DR-8 |

- | DR-8.5 | TH580 | DR-8M |

DR-9 | DR-9 | TH620 | DR-9 |

DR-9M | DR-9.5 | - | DR-9M |

DR-10 | - | - | DR-10 |

Hardness

Temper | Hardness, HR30T | Yield Strength, Mpa | |

Target Value | Range | ||

T-1 | 49 | 49±3 | - |

T-1.5 | 51 | 51±3 | - |

T-2 | 53 | 53±3 | - |

T-2.5 | 55 | 55±3 | - |

T-3 | 57 | 57±3 | - |

T-3.5 | 59 | 59±3 | - |

T-4 | 61 | 61±3 | - |

T-4.5 | 63 | 63±3 | - |

T-5 | 65 | 65±3 | - |

DR-7 | 69 | 69±3 | 480 |

DR-7M | 71 | 71±3 | 520 |

DR-8 | 72 | 72±3 | 550 |

DR-8M | 73 | 73±3 | 580 |

DR-9 | 75 | 75±3 | 620 |

DR-9M | 76 | 76±3 | 660 |

DR-10 | 79 | 79±3 | 690 |

Note: Please pay a special attention to the rolling direction for making cans with DR materials. | |||

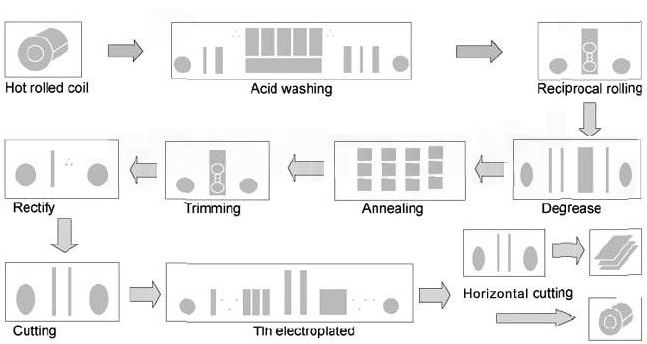

Manufacturing Process

Features

Excellent Corrosion Resistance | By selecting a proper coating weight, appropriate corrosion resistance is obtained against container contents. |

Excellent Paintability & Printability | Printing is beautifully finished using various lacquers and inks. |

Excellent Solderability & Weldability | Tinplate is widely used for making various types of cans by soldering or welding. |

Excellent Formability & Strength | By selecting a proper temper grade, appropriate formability is obtained for various applications as well as the required strength after forming. |

Beautiful Appearance | Tinplate is characterized by its beautiful metallic luster. Products with various kinds of surface roughness are produced by selecting the surface finish of the substrate steel sheet. |

Applicaions

1) Food Cans

2) Beverage Cans

3) Aerosol Cans

4) General Line Cans

5) Tin Bucket

6) Crown Cork

7) Twist-off Caps

8) Easy Open Ends

9) Decorative Cans

10) Sign Board

11) Components

12) Others.

Production

China Metal Group provides the best quality to the customer, we develop cutting-edge solutions in technology, processes, and products. We use the latest technology to improve the quality and the performance of our products, upgrade our manufacturing processes, and use the latest methods in process analysis and design. We always challenge ourselves and have developed into an innovation-driven company.

Package

The products are packed and labeled according to the regulations or customer's requests.

Great care is taken to avoid any damage which might be caused during storage or transportation.

In addition, clear labels are tagged on the outside of the packages for easy identification of the product.

1) Our Standard Seaworthy Packing.

2) According to customer request.